7 Innovations Revolutionizing the Textile and Dyeing Industry

The textile and dyeing industry is experiencing a remarkable transformation. For decades, manufacturers relied on methods that consumed large amounts of water, energy, and chemicals.

Today, consumer demand for eco-friendly products and durable fabrics is driving rapid innovation. Companies are adopting smarter solutions that reduce waste, improve efficiency, and deliver higher performance.

From advanced dyes to digital processes and nanotechnology, new practices are reshaping how fabrics are produced. In this article, you’ll discover seven key innovations that are redefining the dyeing industry and shaping its sustainable, technology-driven future.

1. High-Performance Dyes for Modern Fabrics

Modern lifestyles demand fabrics that can withstand constant use and harsh conditions. Everyday clothing, sportswear, and outdoor gear must hold color even after repeated washing, UV exposure, and friction. This is where high-performance dyes come into play. Manufacturers, like Polyventive, design them to meet durability standards while keeping fabrics vibrant and appealing.

One important example is disperse dyes, which are widely used for synthetic fibers like polyester. These dyes penetrate fibers deeply, resulting in bright, long-lasting shades. Their ability to resist fading makes them a standard in industries that need reliable, high-quality textiles.

Whether for fashion, activewear, or industrial applications, high-performance dyes like disperse dyes are setting the stage for innovation. They bridge the gap between consumer expectations and manufacturer capabilities, proving that performance and beauty can go hand in hand.

2. Eco-Friendly Dyeing Processes

Sustainability has become a central theme in textile production. Traditional dyeing often requires thousands of liters of water for a single batch of fabric. Today, new eco-friendly methods are reducing that footprint. Low-liquor dyeing techniques and waterless processes are gaining attention for their efficiency. Many companies are also switching to biodegradable chemicals that are safer for both workers and the environment. These changes not only support global sustainability goals but also improve the reputation of brands adopting them.

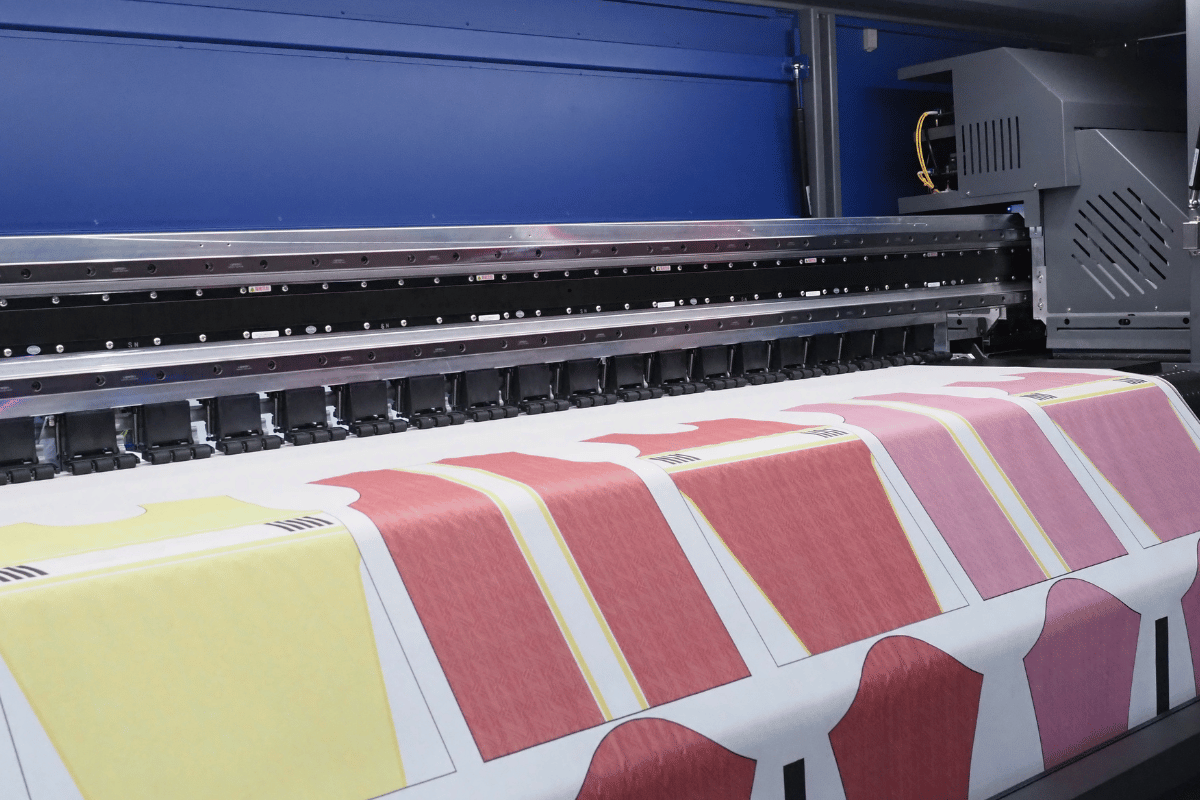

3. Digital Printing in Textiles

Digital textile printing is revolutionizing design and production. Unlike traditional methods, digital printing uses precise, computer-controlled systems that apply dye directly onto fabric.

This process minimizes fabric waste and reduces water usage significantly. It also allows for customization, making small-batch designs affordable and quick to produce. Fashion houses and home décor brands are embracing digital printing to keep up with fast-changing trends.

The flexibility and precision of digital technology make it one of the most promising innovations in the dyeing industry.

4. Smart Color Matching Technology

Color consistency has always been a challenge in textile dyeing. A shade that looks perfect on one fabric may appear slightly different on another. Smart color matching technology, powered by AI and machine learning, is solving this problem.

By analyzing fabrics and predicting dye behavior, these systems create formulas that ensure uniform results. This reduces costly errors and prevents wasted fabric. As automation becomes more advanced, businesses benefit from improved efficiency and higher customer satisfaction.

5. Recycling and Circular Dyeing Methods

The global textile industry is moving toward circular practices, and dyeing is no exception. Recycling wastewater is one of the most impactful changes. Closed-loop dyeing systems allow manufacturers to reuse water, chemicals, and heat, significantly cutting down on resource use.

This approach reduces pollution and lowers operational costs. Circular methods are an investment in the future, helping companies stay compliant with environmental regulations while building consumer trust.

6. Nanotechnology in Dyeing

Nanotechnology is making fabrics smarter and more resilient. By applying nano-coatings, manufacturers can enhance color fastness and add new functionalities. Textiles treated with nanotech may become stain-resistant, antibacterial, or even UV-protective.

These properties open up applications in healthcare, sportswear, and technical clothing. Consumers benefit from garments that last longer and perform better in demanding environments.

Nanotechnology represents one of the most exciting frontiers in textile innovation, merging science with fashion and functionality.

7. Automation and Smart Factories

Automation is changing the face of textile production. Smart factories equipped with robotics and IoT systems are streamlining dyeing processes. Automated machines ensure accuracy in dye application, cutting down human error.

Sensors and data-driven monitoring systems track every step, improving quality assurance while saving energy. This digital transformation allows manufacturers to scale production without sacrificing precision.

For many businesses, smart factories represent the ultimate combination of efficiency, sustainability, and profitability.

Summing Up!

The textile and dyeing industry is moving toward a future that blends sustainability with high performance. From durable disperse dyes to eco-friendly processes, digital printing, and smart factories, innovation is driving every stage of production. These changes not only improve efficiency but also align with consumer demand for quality and responsibility. Companies that embrace these seven innovations are better prepared to compete in a global market that values both performance and sustainability. By adopting new practices today, the industry is shaping a cleaner, smarter, and more colorful tomorrow.