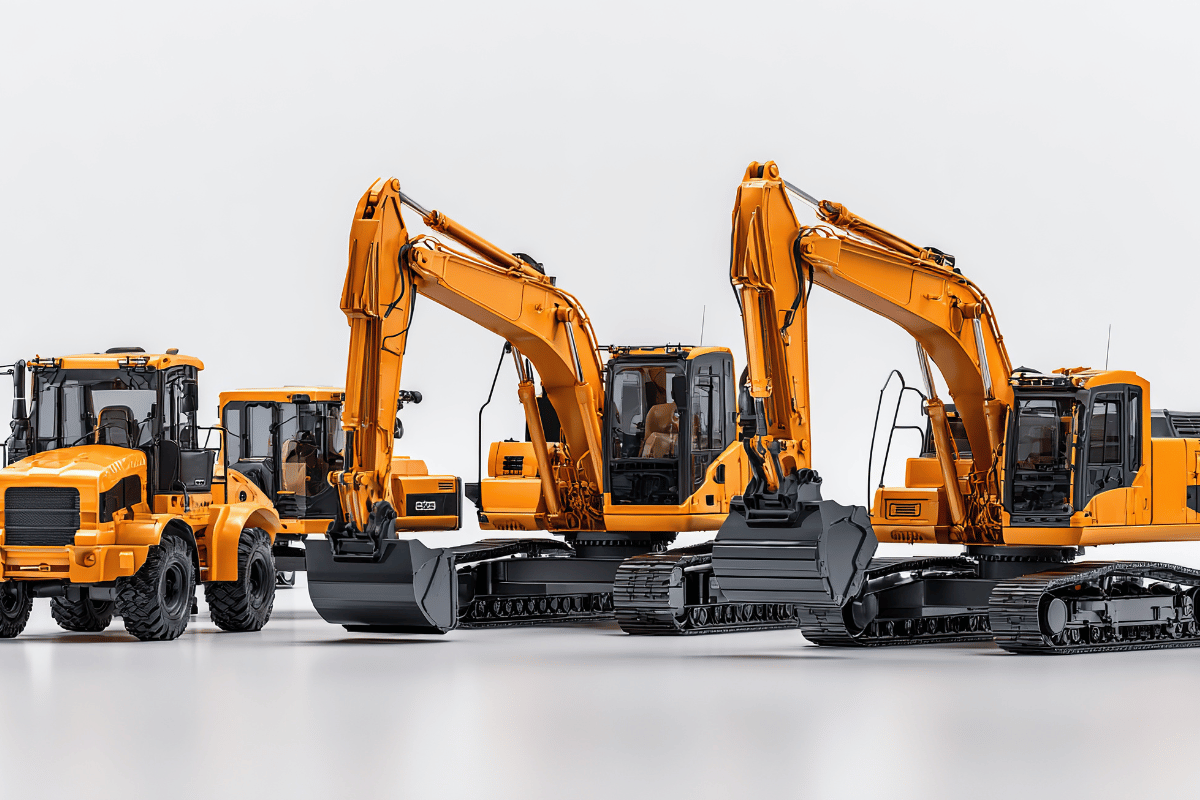

How to Choose Quality Parts That Support Heavy-Duty Vehicle Operations

Heavy-duty operations rely on strong equipment that performs well under pressure. Choosing the right components plays a major role in safety, efficiency, and uptime. Poor quality choices can lead to breakdowns, delays, and higher repair costs. Many operators focus only on price, which often creates problems later. Quality selection requires attention to standards, fitment, and sourcing. Understanding these factors helps reduce long-term risk.

This challenge is common across logistics, construction, and transport operations. Fleets operating in demanding environments need dependable solutions that match workload demands.

This article explains how to evaluate quality standards, select reliable suppliers, compare options, confirm compatibility, and use maintenance data. Each section builds practical insight to support smoother heavy-duty operations.

1. Quality Standards That Impact Performance

Quality standards determine how well components handle stress and repeated use. Material strength is one of the most important factors. High-grade metals resist heat, pressure, and wear over time. Certifications also signal reliability. Recognized standards show that items are tested for consistency and safety. Ignoring these details often leads to early failure.

Performance ratings offer another layer of assurance. Load capacity, temperature tolerance, and durability ratings help match use conditions. Operators should review these details before purchasing. Focusing on standards rather than brand names helps avoid marketing traps. Well-evaluated quality supports longer service life and fewer unexpected issues during daily operations.

Key quality checks include:

- Verified material composition

- Recognized manufacturing certifications

- Performance ratings matching workload demands

2. Selecting Reliable Suppliers for Vehicle Parts

Supplier choice directly affects operational stability. Reliable suppliers focus on consistent sourcing and product availability. They work with manufacturers that meet quality requirements. Experience also matters, since established suppliers understand industry needs and common failure points. This reduces risk during urgent repairs.

Many operators prefer to Shop for auto and heavy duty truck parts through trusted providers like CTR, which focus on dependable sourcing and wide inventory coverage. Access to reliable stock helps minimize downtime. Strong suppliers also offer warranties and basic technical support. This guidance simplifies selection and improves confidence during maintenance planning.

Reliable supplier benefits include:

- Faster access to needed components

- Clear warranty coverage

- Support during selection and installation

Comparing OEM and Aftermarket Parts

OEM options are designed to match original specifications. They are often preferred for critical systems where fit and function are essential. These options usually support warranty protection and system integrity. However, they can be more expensive and slower to source. This makes planning ahead important when choosing this option. Advance ordering helps reduce downtime and supports smoother maintenance scheduling across operations.

Aftermarket options vary widely in build and performance. High-grade alternatives can perform well for non-critical applications. Cost savings may be possible when standards are met. The key is avoiding low-grade alternatives that compromise safety. Smart comparison focuses on function, not price alone. Balanced decisions protect performance while controlling long-term costs. Careful evaluation helps avoid repeated replacements.

Ensuring Proper Fitment and Compatibility

Correct fitment prevents performance issues and unnecessary wear. Matching specifications such as model year, configuration, and system requirements is essential. Incorrect selection can cause alignment problems or system faults. This often leads to repeated repairs. Checking details early helps reduce installation delays. Clear documentation and verified specifications support accurate selection during maintenance planning.

Modern heavy-duty systems also rely on electronic integration. Sensors and modules must communicate correctly with onboard systems. Verifying compatibility before purchase reduces installation problems. Accurate fitment supports smoother operation and protects surrounding components. Attention to detail at this stage prevents avoidable downtime and frustration later. Proper verification saves time during servicing. System-level checks improve long term reliability and reduce unexpected operational disruptions.

Using Maintenance Data for Smarter Decisions

Tracking maintenance history helps identify patterns. Repeated failures may signal deeper issues. Understanding root causes prevents unnecessary replacements. Operational data allows businesses to evaluate which components last longer under real conditions. Consistent records make trends easier to spot.

Maintenance records also support budgeting decisions. Tracking performance over time shows which options deliver value. This helps justify higher upfront costs when long-term savings are clear. Data-driven planning improves reliability and reduces emergency repairs. Better records support more predictable operations.

Helpful tracking practices include:

- Recording installation dates

- Monitoring service intervals

- Comparing performance across brands

Conclusion

Choosing components requires more than quick purchasing decisions. Standards, sourcing, compatibility, and data all play important roles. Reliable suppliers and informed comparisons support safer operations. Thoughtful planning reduces downtime and overall costs. Each decision affects daily performance and operating stability. Clear processes help teams respond better during unexpected maintenance situations. Consistent evaluation improves reliability across demanding work environments. When each step is handled carefully, heavy-duty operations remain efficient and dependable over time.