How to Identify Signs of Gasket Wear Before It’s Too Late

The gaskets are very essential in ensuring integrity of industrial machines since they ensure there is no leakage and they are operating efficiently. Gradually, these parts undergo heat, pressure, chemicals and mechanical stress, which may lead to wear and subsequent failure. It is imperative to note the initial signs of gasket wear in order to prevent expensive downtimes, damage of equipment, and safety issues. Gasket inspection and maintenance is a proactive measure that will help to increase the life of machinery and ensure that the device is operating efficiently.

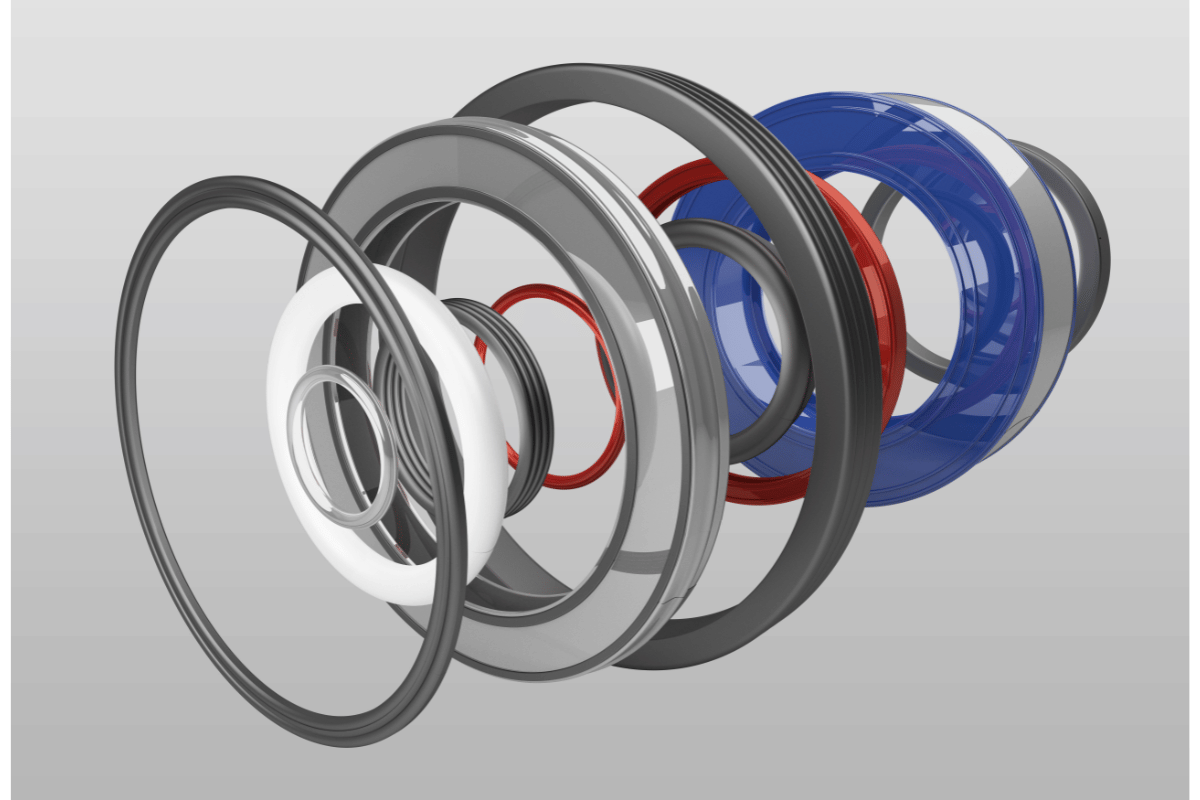

Visual Indicators of Gasket Damage

The initial indication of a gasket that is wearing out is in most instances visible damage. Examine the material around cracks, fraying, or deformation and these are possible signs that suggest that the gasket is ceasing to offer an effective seal. The heat exposure or chemical reaction may also be depicted by discoloration especially in gaskets, which are applied in high-temperature operations using such materials as ceramic fiber insulation. The seal can be easily damaged in minor ways, and it is necessary to address it as soon as possible to avoid the development of additional problems.

Early visual signs may be noticed at routine maintenance and prevent their occurrence to a critical condition. A common example of a wear on the surface is swelling, shrinkage, or irregularities that might remain unseen unless examined rigorously. Recording the conditions of gaskets over the years could assist in monitoring the alterations and allowing the time of their replacement to be anticipated. These practices enable maintenance teams to act early before there is a leakage or failure of the system.

Symptoms of Fluid Accumulation and Leakage

Leaks are a definite sign of a gasket not being able to work as intended. The presence of fluid surrounding the joints or flanges or equipment surfaces may indicate that the seal is broken. Well, even minor leakages are able to decrease the efficiency of the system, contaminate it, or lead to dangerous states. It is important to note that such early leaks should be detected by keen observation during operation or maintenance checks.

The occurrence of persistent or recurrent leaks is usually an indication of underlying wear of the material used in gaskets. Equipment that is subjected to regular pressure variation or vibration is highly vulnerable to leakages. It will be possible to reduce the number of expensive repairs and address the issue right after its emergence. Gasket replacement or repair is also necessary in such circumstances to ensure safe and efficient operations.

Effects of Mechanical Stresses and Deformations

Gaskets that are subjected to constant mechanical force can have signs of compression set or permanent deformation. These problems can decrease the capacity of the gasket to restore to its original shape and give it an appropriate seal. Highly pressured equipment and equipment that is subjected to wash and reassembling are also the most likely to experience this form of wear. Observation of the changes in gasket shape and thickness may permit the intervention to be undertaken.

Along with physical deformation, wear can be aggravated by vibration and movement in equipment, as well. Flange misalignment or incorrect installation may speed up the deterioration and lower the effectiveness of the gasket. Periodical assessment of the mechanical state of affairs by maintenance teams at the areas of gaskets and corrections to avoid untimely breakdown are necessary. These changes can be observed over time and thus planned maintenance can be carried out instead of reactive maintenance.

Material Degradation and Environmental Factors

Gasket materials may deteriorate with time under the influence of chemicals, heat, and environmental conditions. Such materials as fiberglass insulation can be a source of wear in case of exposure to specific chemicals or too much moisture. The knowledge of the environment of operation of the equipment assists in determining the gaskets that face a greater risk of degradation. Proper choice of gasket material depending on the conditions can help a great deal in increasing service life.

Material degradation can be accelerated by environmental factors like changes in temperature, exposure to chemicals and moisture. Even high durable gaskets may fail when the conditions are worse than they are specified. Frequent inspection and material testing should be used to detect placement of degradation before it causes leaks or mechanical breakdown. These environmental factors should be factored in during the maintenance planning so that reliability is maintained.

The case of early warning of the gasket wear is paramount in keeping the industry operations safe, efficient, and cost effective. Through attentive measures on visual indicators, leakage, mechanical pressure, and material deterioration, maintenance teams are able to detect the issue before it runs out of control. Proactive maintenance will be possible by incorporating regular checkups and the knowledge of the environment in which the business is functioning, the impact of materials like ceramic fiber insulation and fiberglass insulation. Early detection of wear is minimizing the downtime, avoids costly repairs, and promotes long-term equipment reliability.